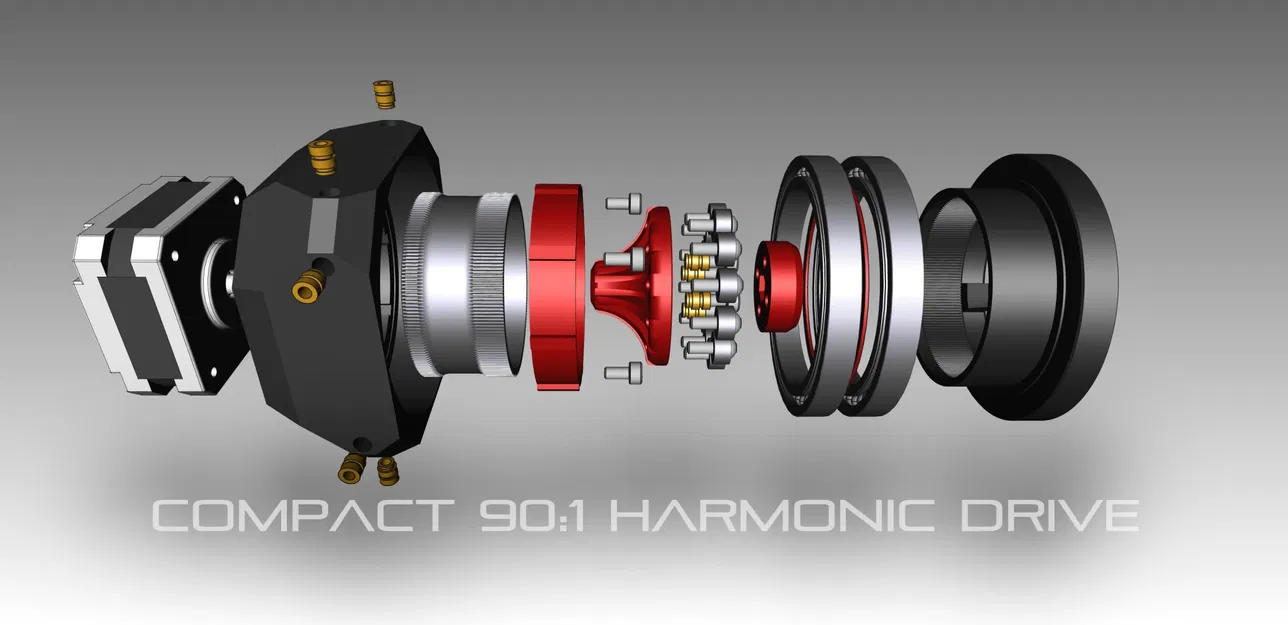

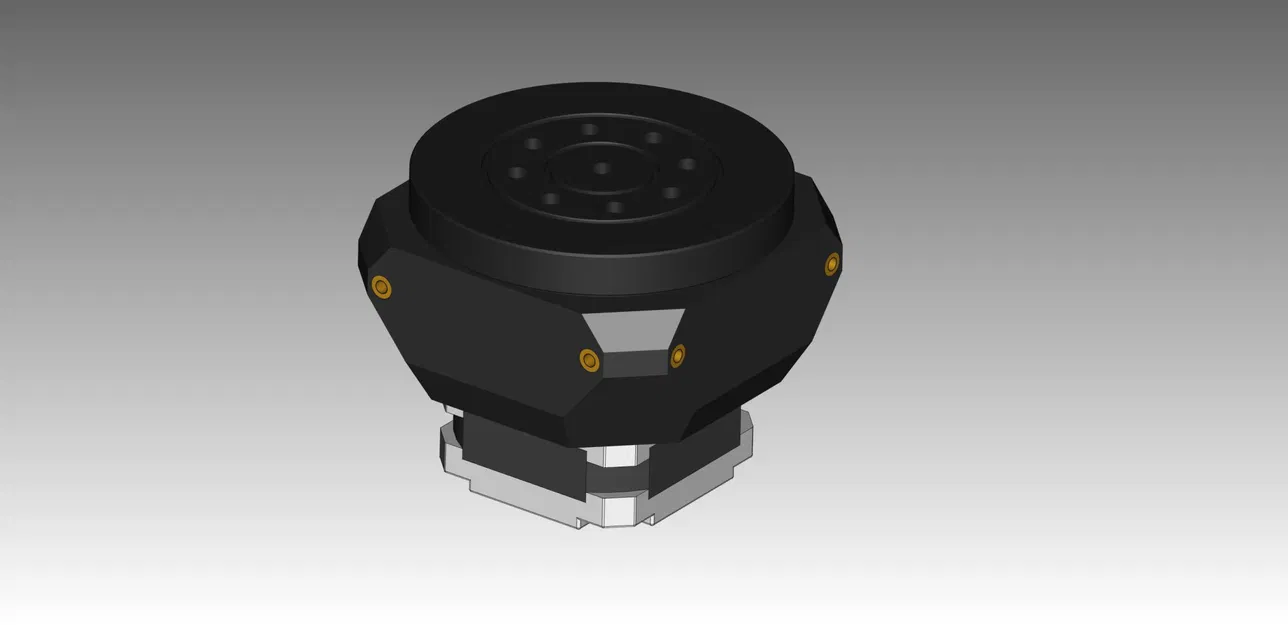

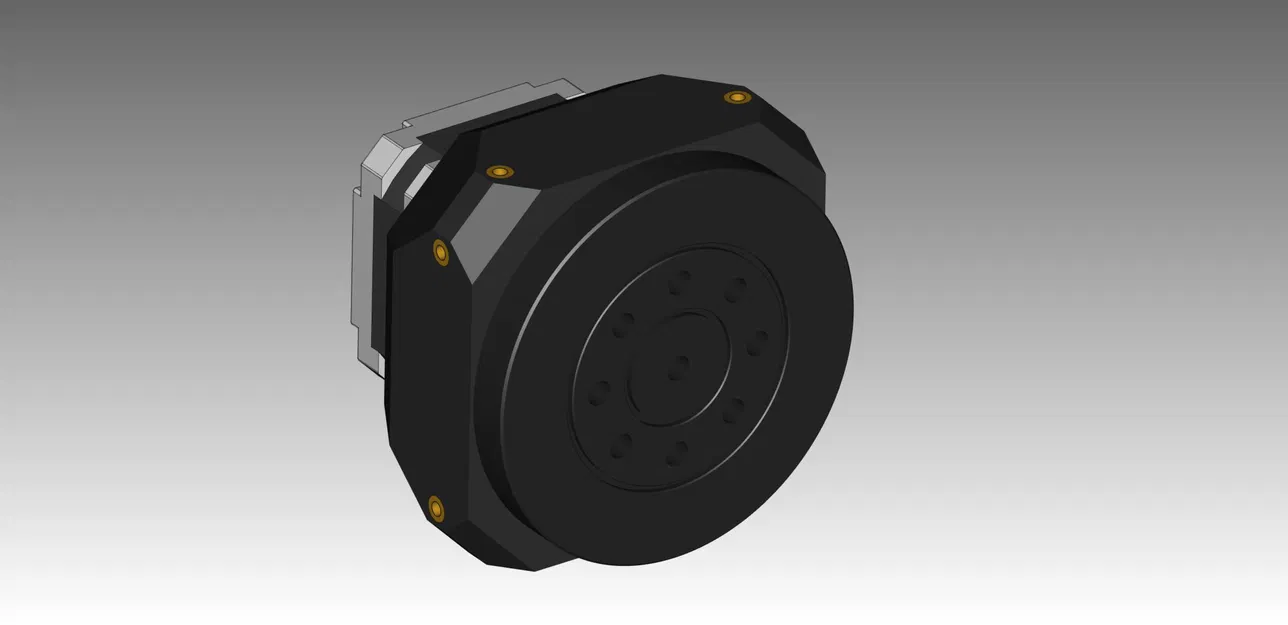

Compact 90:1 Harmonic Drive

Ổ đĩa hài nhỏ nhỏ gọn giảm cao

Mô tả

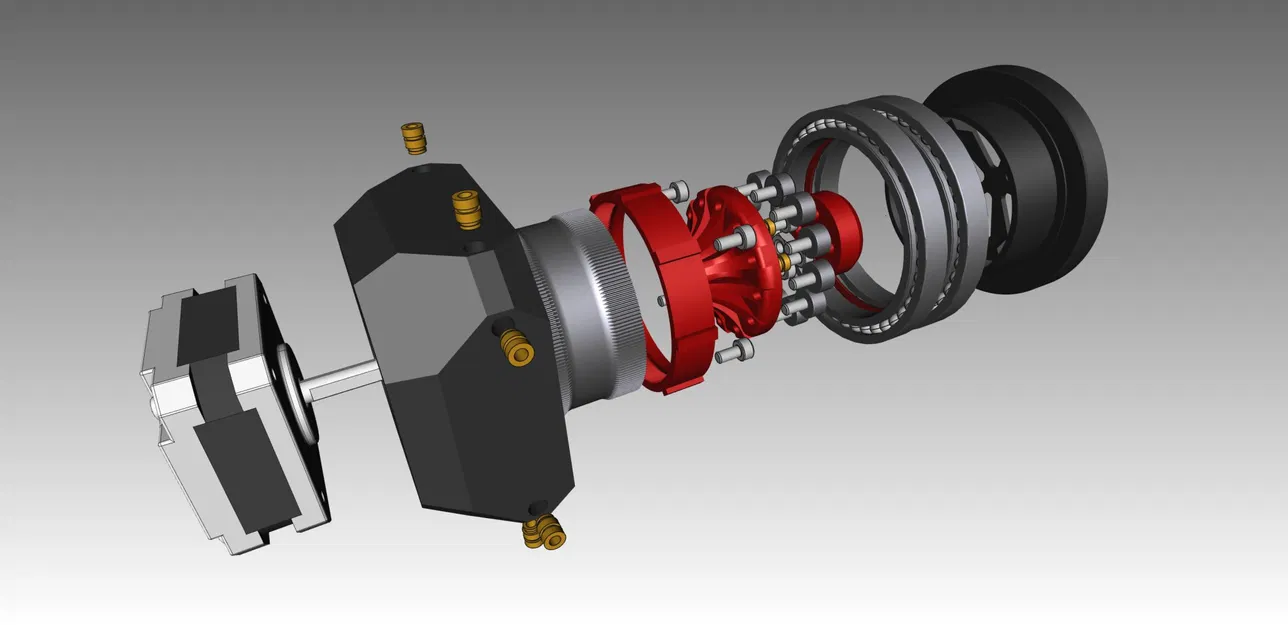

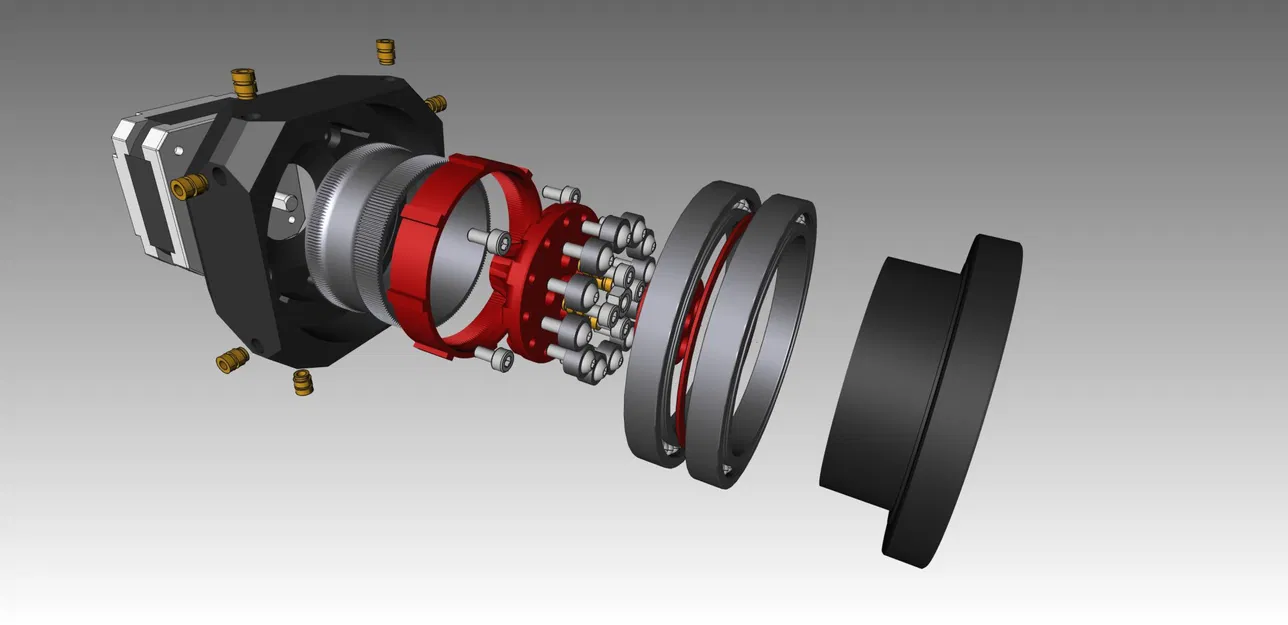

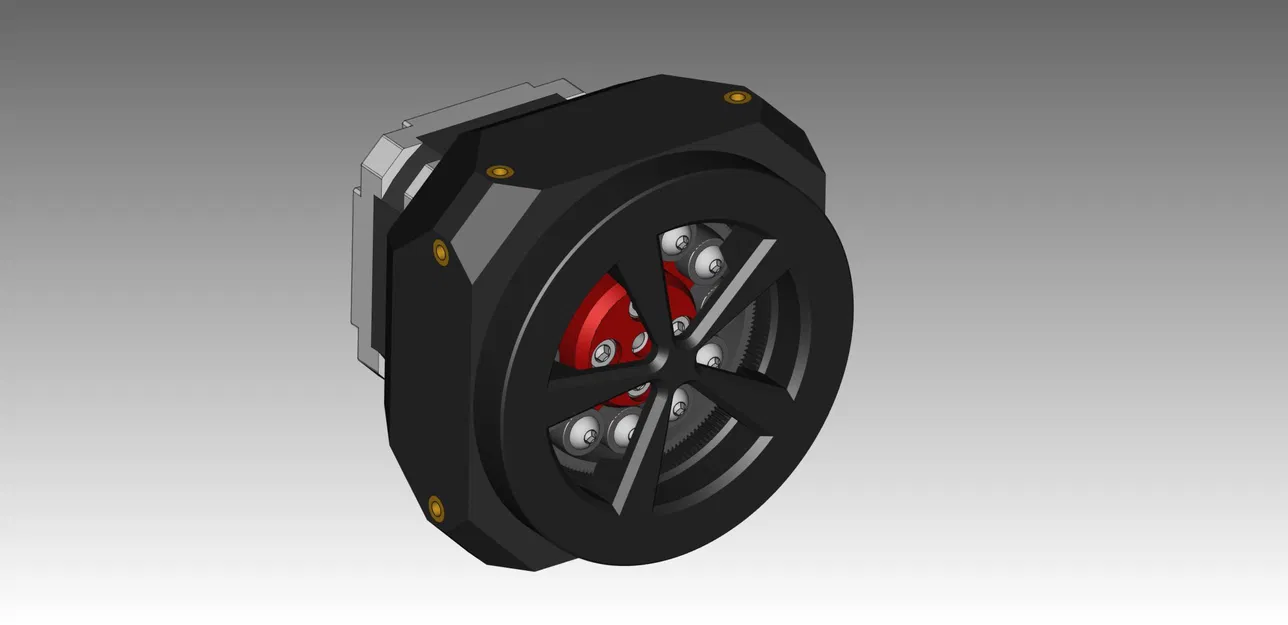

90:1 compact high reduction harmonic drive I wanted to build a Harmonic Drive gearbox that was as small as possible and had the highest possible gear ratio, and that's what came out of it. A 90:1 high reduction Drive. Another goal was to design a flexspline that works almost stress-free. Here, the Flexspline was loosely inserted into a toothing that is connected to the housing with no play and torsion-proof.

The circular spline (output shaft) is held stable in ball bearings, so it does not deform under load. Last but not least, the direction of rotation is the same as that of the motor.

- 12x Bearing 693ZZ (3x8x4) https://amzn.eu/d/gG0BfGJ

- 1x NEMA17 Motor with 5mm D-Cut shaft

- 4x M3x6 allen screws (for motor mounting)

- 16x M3x8 allen screws (Ballbearings, WavegeneratorCap)

- 4x M3 heatset insert 5x4 (Wavegenerator)

- 8x M3 heatset inserts 5x4 (optional for housing)

- 12x M3 shim, or better DIN 988 3x6x0.5

- 1x M4 Hexnut

- Grease #### Printsettings: - Flexspline: 0.2mm nozzle, layerheight 0.1mm, PETG

- Flexspline_Outer_Ring: 0.2mm nozzle, layerheight 0.1mm

- Circular_Output: 0.2mm nozzle, layerheight 0.1mm

- all other parts: you can use a 0.4mm nozzle and a strong material like ABS

- dont try to ptint the toothing with a nozzle greater than 0.2mm, it is not possible! !!! Important !!! These are precision parts with very tight tolerances, so the printer has to be set very well. In order to ensure dimensional accuracy, you must first calibrate your printer best possible. Flow, pressure advance (klipper) linear advance (marlin) and including the shrink factor of the filament, because that makes the difference between success and failure. To calibrate your shrinkfactor, use this: https://www.f3d.vn/3d-model/3271-hieu-chuan-he-so-co-rut-cho-filament-in-3d A disadvantage is that the output shaft is not stable in the Z-axis, you can pull it out. If you want to use this drive, you still have to plan for a bearing for the shaft. To facilitate centering, there are 2 centering aids on the front panel. Happy printing!

Giấy phép

Tác phẩm này được cấp phép theo

Creative Commons — Attribution — Noncommercial — Share AlikeCC-BY-NC-SA

File mô hình

Chưa có bản in nào được khoe. Hãy là người đầu tiên!

Chưa có bình luận nào. Hãy là người đầu tiên!